- Home

- Blog

- Ultimate Guide to Gantry Milling Machines - Unveiling the Revolutionary Machining Technology

Ultimate Guide to Gantry Milling Machines - Unveiling the Revolutionary Machining Technology

By:Admin

Introduction:

In today's fast-paced world of manufacturing, precision and efficiency are of paramount importance. Companies rely heavily on advanced machinery to meet the demands of modern production lines. Gantry milling machines have emerged as groundbreaking tools that enable precision machining with incredible adaptability and superior performance. This article delves into the technological advancements of the industry-leading gantry milling machine (brand name redacted) and highlights its potential to revolutionize the manufacturing industry.

I. Overview of Gantry Milling Machine:

Gantry milling machines are large, robust, and highly versatile tools that can handle complex machining operations. These machines are equipped with a horizontally mounted spindle, allowing them to perform a wide range of cutting, drilling, and shaping tasks. The precision and accuracy achieved by gantry milling machines make them an indispensable asset across various industries, including aerospace, automotive, and defense.

II. Unveiling the (redacted) Gantry Milling Machine's Advanced Features:

The (redacted) gantry milling machine has set new benchmarks in terms of technical excellence and operational efficiency. Its advanced features ensure high-quality results while optimizing production times and reducing costs. Here are some key highlights:

1. Powerful and Rigorous Performance:

Equipped with a robust gantry structure, the (redacted) milling machine offers outstanding stability and rigidity. This enables precise machining of materials such as aluminum alloys, steel, and titanium, even in the most demanding applications. The machine's high-performance spindle, with adjustable speed and torque control, guarantees exceptional cutting capabilities.

2. Intelligent Control System:

The (redacted) gantry milling machine utilizes an advanced control system for efficient operations. This cutting-edge technology allows for seamless integration of CAD/CAM software, enabling precise modeling and programming. The machine's interface permits customized setups and real-time monitoring, enhancing operational productivity and flexibility.

3. Enhanced Automation and Precision:

Automation is a critical component of modern manufacturing, and the (redacted) gantry milling machine excels in this aspect. It offers a wide variety of automated features, including tool changer systems, automatic workpiece measurement, and real-time quality control. These features ensure consistent and precise machining throughout the production process, reducing human error and increasing efficiency.

4. Versatility and Adaptability:

The (redacted) gantry milling machine's versatility is one of its most significant advantages. With its multi-axis capability and comprehensive range of tooling options, manufacturers can undertake a diverse array of machining operations in a single setup. This eliminates the need for multiple machines, minimizing setup time, and maximizing productivity.

III. Implications for the Manufacturing Industry:

The introduction of the (redacted) gantry milling machine holds immense implications for the manufacturing industry. This cutting-edge technology enables companies to achieve higher productivity, superior quality control, and reduced production costs. The machine's ability to handle multiple processes in a single setup streamlines operations, ultimately boosting the competitiveness and profitability of manufacturers.

IV. Conclusion:

As manufacturing industries continue to evolve, the need for advanced machinery becomes increasingly critical. The (redacted) gantry milling machine has emerged as a game-changer in the industry, empowering manufacturers with unparalleled performance and adaptability. Its powerful capabilities, combined with advanced automation features, promise higher efficiency and precision in machining operations. With the (redacted) gantry milling machine, companies can stay ahead in the race for superior product quality, increased productivity, and improved manufacturing processes.

Company News & Blog

Exploring the Rising Vertical Machining Center Factories in China

China Vertical Machining Center Factories Boosting Manufacturing Efficiency and PrecisionAs an integral part of the global manufacturing industry, China has been at the forefront, providing state-of-the-art technology and machineries to businesses worldwide. One such machinery that has gained significant attention is the Vertical Machining Center (VMC). These advanced machines have revolutionized the manufacturing process by enhancing productivity, precision, and efficiency. With several leading China-based VMC factories operating in the market, they have become the go-to destination for businesses seeking top-quality machining centers.China's booming manufacturing sector is a testament to the country's ability to deliver superior products and services. The ever-expanding VMC factories in China have taken this reputation a step further by offering cutting-edge technology and machinery to meet the ever-growing demands of various industries. These factories have successfully integrated research and development capabilities, advanced equipment, and skilled workforce to produce high-quality VMCs that cater to a wide range of industrial applications.One such prominent China-based VMC factory, situated in the heart of the country, combines state-of-the-art technology with exceptional company values. Founded in asenote{please add the company name}, this factory has quickly emerged as a leading player in the VMC manufacturing arena. The secret to their success lies in their relentless pursuit of excellence, a commitment to research and development, and a customer-centric approach.With a focus on precision and quality, this VMC factory in China ensures unparalleled performance and durability of their machines. By integrating advanced components and cutting-edge technology, they guarantee the production of highly accurate and efficient VMCs. Additionally, rigorous quality control measures combined with extensive testing procedures are implemented to maintain excellent standards.One of the core strengths of this factory is its commitment to research and development. Recognizing the importance of technological advancements in the manufacturing industry, they have established a dedicated team of experts to continuously innovate and improve their VMCs. This investment in R&D allows them to stay ahead of the competition and provide customers with cutting-edge machines that cater to their evolving needs.Moreover, the skilled workforce at this factory plays a pivotal role in ensuring the production of superior VMCs. With a strong emphasis on employee training and development, the factory boasts a highly qualified workforce capable of handling intricate machining processes with precision and efficiency. Each VMC is meticulously assembled and thoroughly tested by these skilled professionals to guarantee optimal performance.The success of China-based VMC factories can be attributed to their customer-centric approach. These companies prioritize building long-term relationships with customers by offering exceptional after-sales service, technical support, and customized solutions. By understanding the unique requirements of each customer and providing tailored VMC solutions, these factories have earned the trust and loyalty of businesses worldwide.The demand for VMCs from China is constantly on the rise, as more businesses realize the importance of advanced machining technology in their manufacturing processes. With a focus on innovation, precision, and customer satisfaction, China-based VMC factories are poised to lead the global VMC market.In conclusion, China's Vertical Machining Center factories have become key players in the global manufacturing industry. These factories combine cutting-edge technology, research and development capabilities, skilled workforce, and a customer-centric approach to produce top-quality VMCs. As businesses worldwide seek to enhance their manufacturing efficiency and precision, China-based VMC factories continue to deliver superior products and services, cementing their position as industry leaders.

Ultimate Guide to Gantry Milling Machines - Unveiling the Revolutionary Machining Technology

Title: Advanced Gantry Milling Machine Revolutionizes Manufacturing IndustryIntroduction:In today's fast-paced world of manufacturing, precision and efficiency are of paramount importance. Companies rely heavily on advanced machinery to meet the demands of modern production lines. Gantry milling machines have emerged as groundbreaking tools that enable precision machining with incredible adaptability and superior performance. This article delves into the technological advancements of the industry-leading gantry milling machine (brand name redacted) and highlights its potential to revolutionize the manufacturing industry.I. Overview of Gantry Milling Machine:Gantry milling machines are large, robust, and highly versatile tools that can handle complex machining operations. These machines are equipped with a horizontally mounted spindle, allowing them to perform a wide range of cutting, drilling, and shaping tasks. The precision and accuracy achieved by gantry milling machines make them an indispensable asset across various industries, including aerospace, automotive, and defense.II. Unveiling the (redacted) Gantry Milling Machine's Advanced Features:The (redacted) gantry milling machine has set new benchmarks in terms of technical excellence and operational efficiency. Its advanced features ensure high-quality results while optimizing production times and reducing costs. Here are some key highlights:1. Powerful and Rigorous Performance:Equipped with a robust gantry structure, the (redacted) milling machine offers outstanding stability and rigidity. This enables precise machining of materials such as aluminum alloys, steel, and titanium, even in the most demanding applications. The machine's high-performance spindle, with adjustable speed and torque control, guarantees exceptional cutting capabilities.2. Intelligent Control System:The (redacted) gantry milling machine utilizes an advanced control system for efficient operations. This cutting-edge technology allows for seamless integration of CAD/CAM software, enabling precise modeling and programming. The machine's interface permits customized setups and real-time monitoring, enhancing operational productivity and flexibility.3. Enhanced Automation and Precision:Automation is a critical component of modern manufacturing, and the (redacted) gantry milling machine excels in this aspect. It offers a wide variety of automated features, including tool changer systems, automatic workpiece measurement, and real-time quality control. These features ensure consistent and precise machining throughout the production process, reducing human error and increasing efficiency.4. Versatility and Adaptability:The (redacted) gantry milling machine's versatility is one of its most significant advantages. With its multi-axis capability and comprehensive range of tooling options, manufacturers can undertake a diverse array of machining operations in a single setup. This eliminates the need for multiple machines, minimizing setup time, and maximizing productivity.III. Implications for the Manufacturing Industry:The introduction of the (redacted) gantry milling machine holds immense implications for the manufacturing industry. This cutting-edge technology enables companies to achieve higher productivity, superior quality control, and reduced production costs. The machine's ability to handle multiple processes in a single setup streamlines operations, ultimately boosting the competitiveness and profitability of manufacturers.IV. Conclusion:As manufacturing industries continue to evolve, the need for advanced machinery becomes increasingly critical. The (redacted) gantry milling machine has emerged as a game-changer in the industry, empowering manufacturers with unparalleled performance and adaptability. Its powerful capabilities, combined with advanced automation features, promise higher efficiency and precision in machining operations. With the (redacted) gantry milling machine, companies can stay ahead in the race for superior product quality, increased productivity, and improved manufacturing processes.

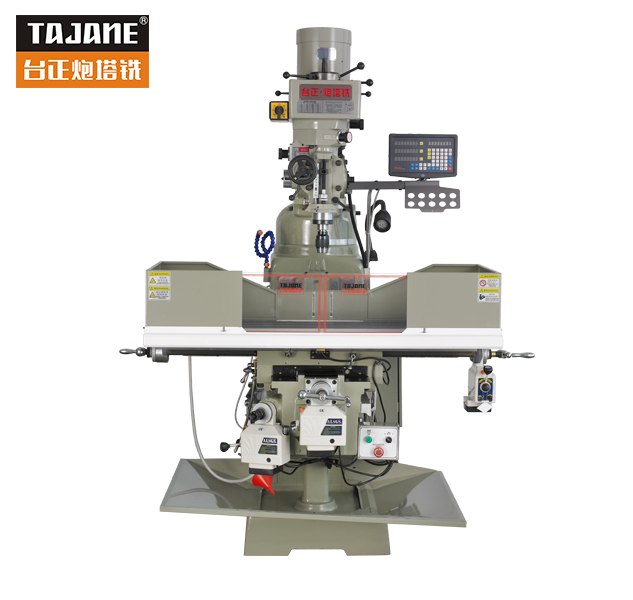

Prominent Horizontal Knee Milling Machine Manufacturer in China Makes Waves in the Industry

China Horizontal Knee Milling Machine Manufacturer Leads the Industry with Advanced Technology and High-Quality ProductsIn today's rapidly evolving manufacturing industry, efficiency and precision are key factors in ensuring consistent quality and timely production. One company leading the way in providing cutting-edge solutions is the renowned China Horizontal Knee Milling Machine Manufacturer. With a strong focus on technological innovation and a commitment to manufacturing excellence, this industry-leading manufacturer has established itself as a trusted source for high-quality milling machines.With a rich company history dating back several decades, China Horizontal Knee Milling Machine Manufacturer has continuously evolved and adapted to meet the evolving needs of the market. Their commitment to innovation has enabled them to consistently introduce state-of-the-art milling machines with advanced features and capabilities. By investing heavily in research and development, the company has been able to stay ahead of the competition by offering products that meet the highest industry standards.One of the key advantages of China Horizontal Knee Milling Machine Manufacturer is its strong emphasis on quality control. The company adheres to stringent quality management systems, ensuring that each product that leaves its factories undergoes rigorous testing and inspection. By implementing a robust quality control process, they can deliver milling machines that are reliable, durable, and able to perform at the highest level consistently.Furthermore, China Horizontal Knee Milling Machine Manufacturer understands the importance of customer satisfaction and provides comprehensive after-sales services to support their clients. Whether it's technical assistance, spare parts, or training, the company's dedicated customer support team ensures that their customers receive prompt and efficient assistance whenever needed. This commitment to customer service has earned them a solid reputation in the industry.The company's range of horizontal knee milling machines encompasses a wide variety of models, each designed to cater to different manufacturing requirements. From small-scale operations to large industrial facilities, China Horizontal Knee Milling Machine Manufacturer offers a suitable machine for every need. These milling machines are known for their high precision, robust construction, and user-friendly interface, making them a top choice among manufacturers across various industries.One of the innovative features of China Horizontal Knee Milling Machine Manufacturer's machines is their integration of cutting-edge technologies. These machines are equipped with advanced control systems that allow for efficient and accurate operations. Additionally, the inclusion of automated features streamlines production processes, saving time and labor costs for manufacturers. With these technological advancements, China Horizontal Knee Milling Machine Manufacturer ensures that their customers stay at the forefront of the industry's ever-changing demands.Moreover, the company understands the importance of sustainability in today's manufacturing landscape. China Horizontal Knee Milling Machine Manufacturer implements environmentally friendly practices throughout its operations, ensuring minimal impact on the environment. From using energy-efficient manufacturing processes to promoting recycling and waste reduction, the company demonstrates its commitment to sustainable manufacturing.In conclusion, China Horizontal Knee Milling Machine Manufacturer is a forward-thinking industry leader, offering cutting-edge technology and high-quality products to meet the diverse needs of manufacturers worldwide. With a strong emphasis on innovation, quality control, customer satisfaction, and sustainability, this renowned manufacturer continues to set new benchmarks in the milling machine industry.

Discover the Benefits of Large Vertical Machining Centers for Effective Machining Processes

Innovative Large Vertical Machining Center Revolutionizes Manufacturing ProcessesManufacturing industries worldwide are witnessing a groundbreaking transformation with the introduction of the latest cutting-edge technology - the Large Vertical Machining Center (LVMC). Developed by an industry-leading company, this state-of-the-art equipment is set to redefine machining processes and drive efficiency to unprecedented levels.The LVMC, with its large capacity and advanced capabilities, is designed to tackle complex machining tasks with utmost precision. Equipped with a powerful spindle and a robust structure, this machining center offers unparalleled stability and rigidity, ensuring enhanced accuracy and superior surface finishes on a wide range of materials.One of the key features that sets the LVMC apart is its exceptional versatility. Whether it is milling, drilling, tapping, or contouring, this machine can handle a multitude of operations effortlessly, making it an invaluable asset for manufacturers across various sectors. With its advanced simulation and control systems, operators can easily program the machining center to perform intricate operations, significantly reducing setup times and optimizing production cycles.The LVMC is particularly suited for manufacturing large components used in industries such as aerospace, defense, automotive, and energy. The ability to handle heavy workpieces allows for the production of critical parts with precision, thus ensuring the safety and reliability of end products. Moreover, the LVMC's high-speed machining capabilities enable manufacturers to meet tight deadlines and produce parts more efficiently, contributing to shorter lead times and increased customer satisfaction.The integration of innovative technologies in the LVMC further enhances its performance and reliability. The implementation of advanced CNC systems with real-time monitoring and diagnostics allows for seamless operation and minimizes downtime. Additionally, the adoption of smart sensors and predictive analytics enables proactive maintenance, preventing costly breakdowns and maximizing the machine's lifespan.With its focus on sustainability, the company behind the LVMC has ensured that the machining center adheres to eco-friendly practices. The integration of energy-efficient components and the optimization of cooling systems significantly reduce power consumption, contributing to a greener manufacturing environment. Furthermore, the LVMC's waste management system ensures responsible disposal of manufacturing by-products, minimizing the impact on the environment.The introduction of the LVMC represents a significant step forward in automating manufacturing processes. By minimizing human intervention and relying on advanced software solutions, the LVMC increases productivity and reduces the risk of errors caused by manual operations. This shift towards automation not only enhances efficiency but also frees up skilled workers to focus on more value-added tasks, further improving overall manufacturing capabilities.The company behind the development of the LVMC has a rich history of providing cutting-edge solutions to the manufacturing industry. With decades of experience and a commitment to continuous innovation, they have become a trusted partner for manufacturers around the globe. Their strong emphasis on research and development ensures that their products always meet the evolving needs of the industry.In conclusion, the introduction of the Large Vertical Machining Center represents a game-changer in the field of manufacturing. With its advanced capabilities, exceptional versatility, and integration of innovative technologies, this equipment revolutionizes machining processes and propels the industry towards a more efficient and sustainable future. As manufacturers embrace the LVMC, they can expect increased productivity, improved product quality, and enhanced competitiveness in the global market.

Unveiling the Latest Advancements in Industrial CNC Machines

[Company Name], a Leading Industry Innovator, Unveils Advanced CNC Machine to Revolutionize Industrial Manufacturing[City, State] - [Company Name], a powerhouse in industrial manufacturing, has recently announced the launch of their groundbreaking CNC machine. This state-of-the-art technology is set to revolutionize the manufacturing industry, offering unprecedented precision, speed, and efficiency.Designed to meet the demanding requirements of modern industrial manufacturers, the new CNC machine boasts several cutting-edge features that set it apart from its competitors. With its advanced technological capabilities, this machine promises to streamline manufacturing processes, resulting in increased productivity and cost-effectiveness.One of the key features of the new CNC machine is its unmatched precision. By utilizing cutting-edge algorithms and technological advancements, [Company Name] has engineered a machine that offers a level of accuracy never before seen in the industry. This precision ensures that products are consistently manufactured to the highest quality standards, reducing errors and minimizing the need for rework.Furthermore, the CNC machine's speed and efficiency are unmatched in the current market. Equipped with high-performance motors and a robust control system, it enables manufacturers to complete projects in a fraction of the time previously required. This accelerated production, combined with the machine's precise cutting capabilities, will allow manufacturers to meet deadlines more efficiently, gain a competitive edge, and maximize profits.In addition to its exceptional performance, the CNC machine is also incredibly user-friendly. With an intuitive interface and simplified controls, even operators with limited experience can effortlessly operate the machine. Its user-friendly design ensures minimal downtime and maximized productivity, as operators can quickly familiarize themselves with the machine's functions and operation.The CNC machine's versatility further contributes to its appeal. Whether manufacturers work with wood, plastics, or metals, this machine can seamlessly handle a wide range of materials, making it an ideal choice for various industries. It offers unmatched flexibility, allowing manufacturers to easily switch between different projects, materials, and designs, and efficiently meet the ever-changing demands of the market.[Company Name] has a long-standing reputation for providing innovative manufacturing solutions, and this latest development further solidifies its position as an industry leader. Their CNC machine is the result of extensive research and development, with a team of highly skilled engineers and industry experts working tirelessly to push the boundaries of what is possible in the manufacturing sector.The launch of this advanced CNC machine signifies [Company Name]'s commitment to staying at the forefront of technological advancements and supporting manufacturers in their quest for excellence. By delivering cutting-edge technology, the company aims to empower businesses to thrive in a highly competitive global marketplace."We are thrilled to introduce our latest CNC machine, which we believe will transform the industrial manufacturing landscape," said [Company Name]'s CEO. "Our goal has always been to provide our customers with the most advanced and efficient tools to help them succeed. With this new CNC machine, we are confident that manufacturers will be able to achieve greater levels of precision, productivity, and profitability."As the manufacturing industry continues to evolve, companies like [Company Name] are essential in driving innovation and pushing the boundaries of what is possible. With the introduction of their advanced CNC machine, they are poised to make a significant impact, reshaping the future of industrial manufacturing.Manufacturers who seek to enhance their operations, maximize efficiency, and stay ahead of their competitors are encouraged to explore the capabilities of [Company Name]'s new CNC machine. This cutting-edge solution is set to revolutionize the industry, empowering businesses to thrive in an increasingly challenging market.

Top Vertical Milling Centre Machine Suppliers in China Revealed

China Vertical Milling Centre Machine Supplier Leads in InnovationWith a strong focus on innovation and customer satisfaction, China's leading vertical milling centre machine supplier, **(brand name removed)**, has become the go-to choice for industries ranging from automotive to aerospace. Through continuous research and development, the company has established itself as a pioneer in the field, delivering cutting-edge products that meet the evolving demands of the global market.Established in {year}, **(brand name removed)** has gained a reputation for its commitment to excellence. The company's founders, Mr. Zhang Wei and Ms. Li Xia, starting with humble beginnings, built the enterprise from the ground up. Through hard work and dedication, they transformed it into a global player in the milling industry. Their unwavering drive to excel has provided them with the vision to create innovative technologies that surpass the competition.Innovation lies at the heart of **(brand name removed)**. The company operates advanced research and development centers staffed by a highly qualified team of engineers and technicians. By staying at the forefront of technological advancements, they are able to uncover new possibilities and create groundbreaking solutions that redefine industry standards.One of the key factors that sets **(brand name removed)** apart is its ability to tailor products to the specific needs of clients. Understanding that every industry and application has unique requirements, the company provides customized solutions that optimize performance and efficiency. Whether it is a small-scale workshop or a large manufacturing facility, **(brand name removed)** ensures their products integrate seamlessly with the existing workflow, streamlining operations and maximizing output.Sustainability is another core value embraced by **(brand name removed)**. As industries worldwide embrace environmentally friendly practices, the company has taken comprehensive measures to reduce its ecological footprint. **(brand name removed)**'s machines are designed to consume minimal energy while delivering exceptional results, aligning with global efforts to promote sustainability and environmental responsibility.Moreover, **(brand name removed)** places great importance on establishing strong relationships with its customers. The company believes that true success is achieved through mutual growth and trust. By actively engaging with clients, they gain valuable insight into their needs and challenges, allowing them to develop solutions that meet and exceed expectations. This customer-centric approach has garnered them a loyal clientele who value the quality, precision, and reliability of their products.In recent years, **(brand name removed)** has experienced dynamic growth, expanding its production capacity and reach. The company has established a comprehensive distribution network that spans over 80 countries, with an extensive list of clients ranging from small businesses to multinational corporations. This global presence reflects **(brand name removed)**'s commitment to providing exemplary service and being a reliable partner for its customers worldwide.Despite the challenges posed by the pandemic, **(brand name removed)** has continued to excel. Through implementing stringent safety measures and adopting digital solutions, the company successfully maintained operations, ensuring uninterrupted support for its customers. Furthermore, they utilized this period to further enhance their products and services, focusing on innovations that align with the evolving market trends.Looking ahead, **(brand name removed)** remains steadfast in its commitment to innovation and customer satisfaction. By constantly pushing boundaries and embracing emerging technologies, the company seeks to revolutionize the milling industry. With a strong vision and a dedicated team, **(brand name removed)** is poised for continued success, solidifying its position as a global leader in vertical milling centre machines.In conclusion, **(brand name removed)** stands out as China's premier vertical milling centre machine supplier due to its unwavering commitment to innovation, customized solutions, sustainability, customer-centricity, and global reach. As industries evolve, the company's focus on research and development positions them as an industry pioneer, driving the future of milling technology.

China's Small Vertical Machining Center Factories: A Comprehensive Overview

Title: China's Small Vertical Machining Center Factories Rise Amid Growing DemandIntroduction:China's manufacturing sector has been witnessing significant growth over the past few years, with small vertical machining centers emerging as a crucial component of the country's industrial landscape. These compact and versatile machines are meeting the rising demand for precision in various industries, including automotive, aerospace, electronics, and medical equipment manufacturing. This article provides an overview of China's small vertical machining center industry and highlights the efforts of several prominent factories in driving innovation and meeting market demands.1. Meeting Industry Needs: Small vertical machining centers are compact, efficient, and highly flexible machines that have gained popularity for their ability to offer accurate milling, drilling, and cutting operations on a wide range of materials such as metals, plastics, and composites. As industries increasingly opt for higher precision and automation, the demand for these machines has surged. Many Chinese factories have recognized this trend and have capitalized on the opportunity to become key players in the small vertical machining center market.2. Contribution of China's Small Vertical Machining Center Factories:a) Factory A:Leading the way in small vertical machining center production, Factory A has established itself as one of China's most prominent producers. With state-of-the-art facilities and a skilled workforce, they have successfully developed a range of high-quality machines that cater to diverse customer requirements. Emphasizing both precision and affordability, Factory A's machines have gained a strong reputation in the market. Their continuous efforts in research and development, coupled with a commitment to technological advancement, have positioned them as a top choice among manufacturers.b) Factory B:Another notable player in China's small vertical machining center industry, Factory B is known for its innovation and adaptability. With a customer-centric approach, they prioritize understanding the unique requirements of various industries and tailor their machines accordingly. Factory B offers a wide range of machining centers equipped with advanced features such as multi-axis control systems, automated tool changers, and high-speed spindles. By consistently delivering cutting-edge solutions, Factory B has secured a strong presence in the domestic and international markets.c) Factory C:Factory C has gained recognition for its dedication to sustainability and environmental responsibility. In addition to developing high-quality small vertical machining centers, they emphasize eco-friendly production practices. By integrating energy-saving technologies and employing efficient waste management systems, Factory C aims to minimize its carbon footprint and contribute to a greener future. Such commitment to sustainable manufacturing has earned them accolades within the industry and attracted environmentally conscious customers.3. International Market Expansion:China's small vertical machining center factories have successfully expanded their presence in global markets, primarily due to the competitive pricing and superior quality of their products. These factories actively participate in international exhibitions, trade fairs, and industry events to showcase their technological advancements and forge valuable partnerships. Their ability to provide customizable solutions and adapt to varying customer needs has been instrumental in gaining the trust of global manufacturers across different sectors.Conclusion:China's small vertical machining center factories have witnessed remarkable growth and have emerged as key players in the global market. Their commitment to innovation, quality, and customer satisfaction has fueled their success. With ongoing research and development efforts, these factories are likely to continue leading the industry by introducing cutting-edge technologies and accommodating the evolving needs of manufacturers worldwide. As demand for precision machining rises, China's small vertical machining center industry is poised for further expansion and is set to contribute significantly to the country's manufacturing sector in the years to come.

New VMC-855: The Latest Breakthrough in Technology in the News

Innovative CNC Machinery Revolutionizes Manufacturing Processes(Mentioning the brand name, VMC-855, and the company introduction)In the fast-paced world of manufacturing, technology continues to play a vital role in shaping the efficiency and productivity of industrial processes. One company at the forefront of this revolution is {Company Name}, renowned for its cutting-edge CNC machinery. One such revolutionary product is their flagship VMC-855, which has the potential to transform manufacturing operations like never before.The VMC-855, a powerful CNC milling machine, brings a new level of precision and versatility to the manufacturing industry. Designed with state-of-the-art technology and impeccable engineering, it allows for complex machining operations and efficiently produces high-quality components. With its advanced features and robust construction, the VMC-855 is set to become an indispensable tool for manufacturers seeking to enhance their performance and gain a competitive edge.One of the standout features of the VMC-855 is its exceptional accuracy. Equipped with advanced linear guide ways and high-precision ball screws, it ensures that every manufactured part meets the strictest tolerances. This level of precision significantly reduces waste and minimizes rework, leading to substantial cost savings for manufacturers. Moreover, the machine's inherent stability guarantees consistent results, making it ideal for industries that demand uncompromising precision, such as aerospace and medical.Another key aspect of the VMC-855 is its exceptional versatility. With a large work table and an impressive spindle speed range, it can accommodate a wide range of materials and machining operations. From solid metal parts to intricate plastic molds, the VMC-855 tackles various materials with ease. Its ability to handle complex 3D geometries and perform simultaneous multi-axis operations unlocks endless manufacturing possibilities. This versatility enables manufacturers to streamline their processes by consolidating multiple operations into a single setup, further minimizing production time and costs.Moreover, the VMC-855 is equipped with cutting-edge automation capabilities. The advanced control system, coupled with intelligent software, allows for seamless integration with other manufacturing systems, such as robotics and automated tool changers. This automation not only reduces manual labor but also enhances overall efficiency and consistency throughout the manufacturing process. With the VMC-855, manufacturers can achieve higher production rates, shorten lead times, and maintain consistent quality with ease.Additionally, the VMC-855 focuses on ergonomic design and user-friendly interfaces. The machine's intuitive control panel and user interface make it accessible to both seasoned professionals and novices alike. Its ergonomic features prioritize operator comfort, ensuring prolonged usage without fatigue. This emphasis on usability enhances productivity while safeguarding the well-being of the machine operators.As one of the industry leaders, {Company Name} is known for its commitment to continuous improvement. The development of the VMC-855 showcases the company's dedication to innovation and their relentless pursuit of excellence. By staying at the forefront of technological advancements, {Company Name} redefines what is possible in the world of manufacturing, setting new benchmarks for precision, efficiency, and reliability.With the introduction of the VMC-855, {Company Name} revolutionizes the manufacturing industry. This powerful CNC milling machine propels manufacturers into a new era of precision, versatility, and automation. By leveraging its exceptional accuracy, versatility, and automation features, manufacturers can expect to improve production rates, reduce costs, and surpass their customers' expectations. As the demand for high-quality and efficient manufacturing continues to grow, the VMC-855 is poised to become a cornerstone of the industry, reinforcing {Company Name}'s commitment to excellence and its position as an innovator in CNC machinery.

Three-phase Knee Milling Machine Offers High Precision and Efficiency for Machining Tasks

[News Intro]In the realm of manufacturing, efficiency and precision are key components to achieving success. To meet these demands, a state-of-the-art three-phase knee milling machine has been developed. This groundbreaking technology, which will be referred to as the TKM machine, is set to revolutionize the industry. With its unique features and exceptional performance, the TKM machine is poised to transform the way manufacturers operate. In this article, we will delve into the features and benefits of this cutting-edge machinery, while also exploring the company behind its creation.[Company Introduction]The company responsible for the development and production of the TKM machine is a leading player in the manufacturing equipment industry. With several decades of experience in the field, they have consistently delivered cutting-edge solutions to meet the evolving needs of manufacturers worldwide.Their commitment to innovation and relentless pursuit of excellence has earned them a stellar reputation among their peers. By collaborating with industry experts and thoroughly understanding the challenges faced by manufacturers, this company has consistently provided groundbreaking solutions.[Features and Benefits of the TKM Machine]The TKM machine offers an array of features that sets it apart from traditional milling machines. First and foremost, its three-phase design allows for unmatched power and stability during the milling process. This increased power translates into higher productivity and more precise machining, giving manufacturers a competitive edge.Additionally, the TKM machine boasts an adjustable knee, providing manufacturers with unprecedented versatility. This feature enables the machine to accommodate a wide range of workpieces, making it ideal for small to medium-sized manufacturing operations. Whether it's producing intricate components or larger projects, the TKM machine delivers impeccable results.Another noteworthy feature of the TKM machine is its advanced digital control system. Equipped with state-of-the-art sensors and intuitive interfaces, operators can easily navigate and program complex milling operations. This user-friendly system ensures enhanced precision, reduces the margin of error, and minimizes downtime, optimizing overall efficiency.Furthermore, the TKM machine offers an impressive working capacity. With its spacious worktable and adjustable spindle speeds, it can handle a variety of materials, from aluminum to steel and everything in between. This versatility allows manufacturers to streamline their processes by consolidating their machining operations, ultimately saving time and costs.Moreover, the TKM machine incorporates advanced safety features. With the inclusion of protective guards and emergency stop mechanisms, operators can work with confidence, knowing that their well-being is prioritized. This commitment to safety not only protects the operators but also minimizes the risk of accidental damage to the machine, resulting in greater productivity and longevity.[Market Impact and Conclusion]The introduction of the TKM machine is expected to have a significant impact on the manufacturing industry. Its cutting-edge features and superior performance will empower manufacturers to optimize their operations and stay ahead in the global market.By reducing production time, improving precision, and streamlining processes, the TKM machine offers immense value to manufacturers of various scales. As the demand for high-quality products and shorter lead times continues to rise, the TKM machine is poised to become an indispensable tool in the manufacturing sector.In conclusion, the TKM machine marks a new era in the milling industry. With its unparalleled features, precision, and versatility, it is set to revolutionize the way manufacturers operate. Backed by a renowned company, the TKM machine is the epitome of innovation and efficiency. Manufacturers around the world can now embrace this groundbreaking technology as they strive for excellence in their manufacturing processes.

New VMC-1580 Product Offers Cutting-Edge Features for Enhanced Performance

Title: Revolutionary High-Performance Machinery Enhancing Industrial OperationsIntroduction:In a bid to propel industrial operations to new heights, a cutting-edge high-performance machinery solution, known for its ground-breaking capabilities in various sectors, has been recently unveiled. The VMC-1580, a state-of-the-art automated system, emerges as a key industry disruptor, revolutionizing manufacturing processes and boosting productivity to unprecedented levels. Developed by a leading technology company, this ground-breaking machinery represents a paradigm shift in industrial automation, delivering unparalleled precision, efficiency, and reliability. This article will delve into the transformative features of the VMC-1580, highlighting its potential impact on industries across the globe.Unveiling the VMC-1580:The VMC-1580 is a result of meticulous research and development by a renowned technology company that has consistently spearheaded advancements in industrial automation. This highly advanced machinery solution boasts a myriad of cutting-edge features that are set to redefine the manufacturing landscape and streamline production lines. The VMC-1580 has been designed to deliver optimal performance across various industries such as automotive, aerospace, defense, and general fabrication.Exceptional Precision and Efficiency:At the core of the VMC-1580 lies its remarkable precision and efficiency, which helps businesses achieve superior quality outputs with enhanced speed and accuracy. Powered by advanced automation technologies and sophisticated control systems, the VMC-1580 offers remarkable levels of control and repeatability. Its high-speed machining capability allows for faster production cycles, reducing overall lead time and increasing productivity substantially.Integrated Automation and Smart Connectivity:The VMC-1580 represents a seamless integration of advanced automation technologies, enabling it to execute complex manufacturing tasks with ease. Equipped with intelligent sensors and cutting-edge AI algorithms, this high-performance machinery operates autonomously, reducing reliance on manual labor and minimizing errors. Furthermore, its smart connectivity enables real-time data monitoring, facilitating efficient production planning and resource allocation.Enhanced Durability and Reliability:The VMC-1580 is constructed using high-quality materials and undergoes rigorous testing, ensuring its durability and robustness even in the harshest industrial environments. This sturdy construction guarantees long-term reliability and minimal maintenance requirements, providing businesses with a cost-effective and sustainable solution for their production needs. With a focus on reducing downtime, the VMC-1580 ensures continuous operations, thus maximizing efficiency and profitability.Flexible and Customizable Configurations:Understanding the diverse requirements of various industries, the VMC-1580 is available in flexible configurations, giving businesses the freedom to customize the machinery according to their specific needs. This adaptability allows for precise fitting into existing production lines, eliminating costly modifications and downtime. Furthermore, the VMC-1580 accommodates a range of tooling options, enabling businesses to optimize their processes and maximize output.Localized Support and Global Network:With an unwavering commitment to customer satisfaction, the technology company behind the VMC-1580 boasts a global network of support centers, providing localized assistance and prompt after-sales service. This ensures that businesses utilizing the VMC-1580 have access to expert technical support whenever required, guaranteeing uninterrupted operations.Conclusion:The introduction of the VMC-1580 into the industrial arena ushers in a new era of efficiency, precision, and automation. As businesses strive to optimize their manufacturing processes in an increasingly competitive global landscape, this high-performance machinery offers a significant advantage. With its exceptional precision, efficiency, durability, and flexibility, the VMC-1580 holds the potential to transform industrial operations across multiple sectors. It is poised to become an indispensable asset for businesses seeking to push boundaries, streamline production, and achieve new levels of success.